In the cable manufacturing business, accuracy is more important than ever. Whether it is a single wire used in a home appliance, or a sophisticated high-tech industrial cable, even a slight difference in diameter or insulation depth can affect safety, efficiency, and overall quality.

SIPCON’s Cable Diameter and Insulation Thickness Measurement Systems allow the manufacturer to perform fast, real-time measurement, non-contact readings. This ensures every cable produced will be following the highest standards, providing reliability and performance you can count on.

Take a power cable supplying electricity across a factory floor. If the insulation is too thin, it could overheat, or there could be a leak, which raises a safety issue. On the other hand, if the insulation is more than thick enough, the manufacturer has wasted some insulation, and may have made that cable at a higher price. Importantly, a cable that is a particular diameter must hold precision tolerances for performance, fit, and usability in the field.

For Indian manufacturers, more so for those serving their local market or exporting across the world précised measurement is important for several reasons:

If India-based producers ensure accurate measurement, quality improves, these manufacturers save on costs and timeliness of production, and ultimately, these manufacturers build their reputation of reliable and high-performance cables to the marketplace.

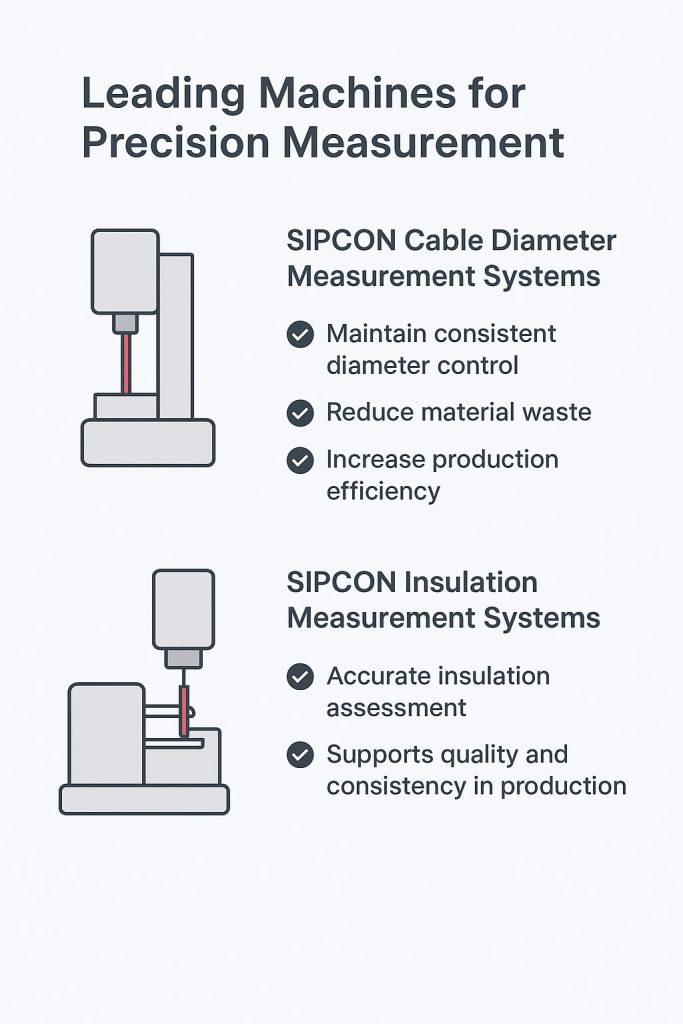

SIPCON cable diameter measurement systems

High performance non-contact system used to detect cable diameter in real-time. Systems employing diameter measurement for maintaining consistent diameter control, reducing material waste, and producing increased efficiencies through the production process.

SIPCON Insulation measurement systems

Measurement systems specially designed for insulated wire and cable applications. They assess the depth of the insulation, by way built with innovative optical systems and/or laser technology.

SIPCON Cable Diameter Measurement Systems

SIPCON Insulation Measurement Systems

Differentiation of cable diameter measurement and insulation thickness measurement based on typical industry requirements:

| Industry / Application | Key Requirement | Cable Diameter Measurement Focus | Insulation Thickness Measurement Focus |

|---|---|---|---|

| Power Transmission & Distribution | High electrical load& safety | ensure conductor accuracy size for current flow rating | Correct insulation to prevent overheating and leakage |

| Automotive | Compact design, vibration resistance | Accurate cable sizing suitable for narrow spaces | Uniform insulation for thermal and Physical protection |

| Electronics & Semiconductor | Micro-level precision | Very small diameters measured with high accuracy | Very thin Covering, accurate layering necessary |

| Industrial Machinery & Robotics | Durability, continuous operation | Maintain consistent diameter for machine compatibility | Thick and durable insulation for wear and abrasion |

| Industrial Machinery & Robotics | Durability, continuous operation | Maintain consistent diameter for machine compatibility | Thick and durable insulation for wear and abrasion |

| Aerospace & Defense | Extreme environmental conditions | Lightweight and précised conductor sizing | High-performance insulation for temperature/pressure extremes |

| Renewable Energy (Solar/Wind) | Long-term durability | Accurate conductor size for power efficiency | UV-resistant and weather-proof insulation depth |

| Household & Construction | Cost efficiency, safety | Standard diameter for current carrying | Sufficient insulation to meet safety codes |

Choosing the accurate measurement system is important for product quality and production efficiency. These are some key considerations:

• Recognize Cable Type

Multiple cables types for power, communication are often necessary in industrial settings for different cable type and insulation

• Consider Production Speed

High production Speed are benefited from SIPCON’s real-time, non-contact measurement systems that operate without halting production.

• Confirm Tolerance Levels

In critical applications (like automotive, aerospace, and power distribution) with tolerances, accurate measurement is necessary and the SIPCON solution accurately measures small tolerances to confirm uniform guidelines.

• Establish Total Cost of Ownership (TCO)

Measurement devices have a high price to purchase but while unlocking major savings on the production end over time by reducing scrap, rework, and down time, and a SIPCON system is a long-term investment.

Selecting the appropriate system for cable diameter and depth of insulation is an investment in safety, quality, and dependability. With SIPCON’s state-of-the-art measurement systems, Indian manufacturers will be able to decrease material waste, avoid mistakes, and produce cables which conform to both Indian and International specifications.

Upgrade your cable manufacturing processes with SIPCON Technology.

Contact one of our experts today for a consultation at info@sipconinstrument.com Learn how SIPCON Cable Diameter and Insulation Thickness Systems can improve your production line efficiency and assured quality. Visit us at https://www.sipconinstrument.com Phone: +91 82229 29966

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi