Electric cable and cable production industries, one element remains constant: cables must be processed with a cleanliness, safety and precision before they progress to the next stage of testing or assembly. From reducing size and weight while increasing overall performance, down to solving the demands of more complex cable designs, like power cables, automotive wire/duplexed wire or householders wires even specific industrial special-purpose cables., three operations are important in everyday production and during your quality checks.

Little Things Mean a Lot While these are basically simple steps on the face, they have a direct bearing on quality, conformance, safety and tensile strength requirements insulation resistance and compliance with industry standards. Failed stripping or improper punching can result in conductor damage, improper testing, insulation tears or failed quality inspections. Many Indian manufacturers are now turning from traditional manual ways and forwarding precision in machine-assisted tools and testing equipment provided by the likes of SIPCON Technologies known for their cable testing & metrology ecosystem.

In this post, we discuss why each is critical to the end use appearance, the optimal equipment available and widely used in India, how SIPCON has been serving manufacturers with dependable, operator friendly and extremely accurate solutions.

In any cable plant Mumbai, Delhi, Pune, Bhiwadi, Chennai or Surat that you may enter you’ll see that stripping and punching and chipping has ceased to be mere of minor movements. They directly affect:

The cleanliness of the insulation removal or preparation is critical to every aspect of cable testing, from measuring to high-voltage testing. With their much stricter QC requirements and customers requiring proof of test results, the days of “feel” being an acceptable method of production for Cable Stripping, Punching and Chipping are over.

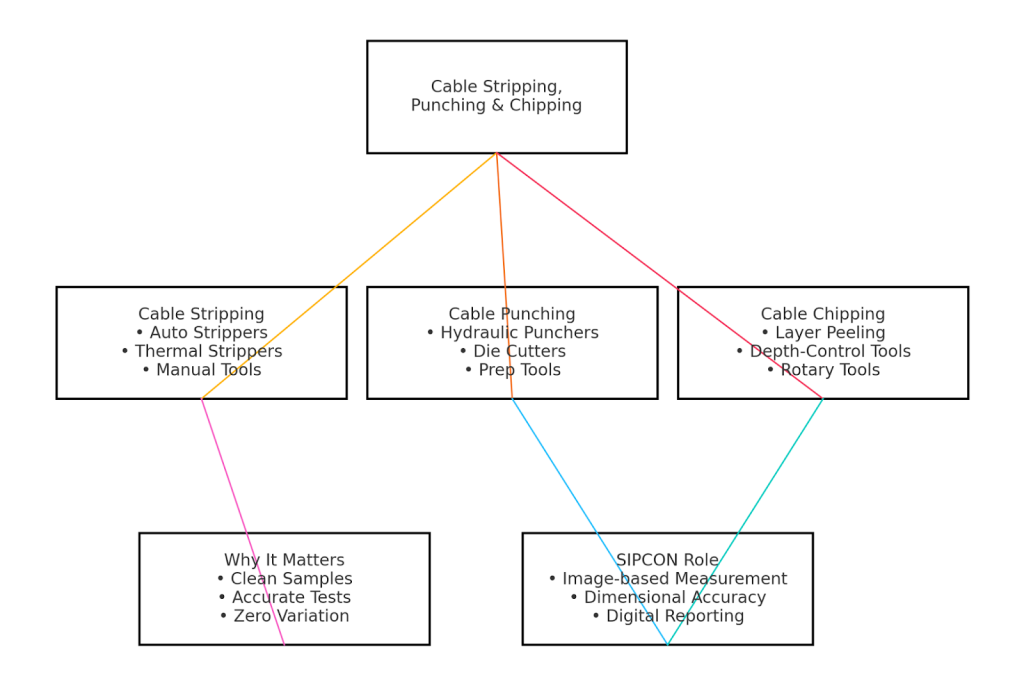

Starting with cable stripping This is usually the first, and in many cases, the most-important of the steps. The idea is to remove the insulation without scaring, nicking, or deforming the conductor strands. Best Equipment for Cable Stripping

a) Automatic Cable Stripping Machines : Ideal for high-volume manufacturers. They offer:

Automatic strippers are ideal for automotive wiring, appliance cables, control cables and multicoated cabling.

b) Semi-Automatic Pneumatic Strippers : Best for medium-scale plants. They are:

c) Thermal Strippers: Used for extra fine wire such as:

Stripping softened by the heat of the conductor to guarantee no damage caused by the stripper.

d) Manual Precision Stripping Tools Still common in India, but more often used is the charcoal chula (Fig. But, from operator to operator, the accuracy rates vary).

Punching is primarily used to produce a clean cross section, or test coupon for the cable. It is typically needed for:

a) Acceptable Hydraulic or Pneumatic Punching Devices

These create clean, repeatable geometry important to obtaining reliable test results.

b) Hand-Operated Punch Tools

c) Precision Die-Based Cutters

For use when precise dimensions are critical for:

5. Cable Stripping: Taking Insulation Off for Measurement

Chipping is generally something those outside of the cable world don’t understand. In simple words: Chipping is the partial removal of insulation from a cable to expose layers for measurement, testing or inspection. Chipping is crucial for:

6. Best Equipment for Cable Chipping

a) Chipping/Peeling Devices: Quick Peel™ Hand & Bench Tools Hand-held and semi-automatic tools especially manufactured for careful stripping of insulation.

b) Precision Utility Knives with Depth Guides-Controlled: It is suitable for small tasks or sample work.

c) Rotational Peeling Tools: Great for those multi-layer cables when you don’t want to cut into the inner ones.

7. The Role of SIPCON Technologies in These Cable Operations

SIPCON Technologies is recognized all over India for its precision’s measurement device particularly in cable and the rubber & plastic industry. And although they may not produce stripping/punching machines themselves, both they and IGRALUBE are key players in quality control that takes place after these operations! And this is where SIPCON comes into play:

8. SIPCON image-based measuring systems deliver:

In this way, errors occurring during stripping, or chipping are rapidly detected.

9. For Tensile, Elongation, Hot Set & Deformation Testing

Test samples are prepared with punching tools. After samples are readied, SIPCON’s systems assist in confirming:

These dimensions also relate indirectly to other standards such as:

Variability among operators is one of the most significant challenges in India. SIPCON eliminates this with:

It allows for more consistent, quality labs and the ability to get audited.

10. Reducing QC Laboratory Turnaround Time

By eliminating the risk of spending too much time on manual microscopy or eyeballing dimensions, SIPCON systems save labs time. This improves:

For Use With Tool For Use On When selecting tools for Cable Stripping, Punching, and Chipping then use:

We re working hard to make tools that not only get the job done but also fit into your inspection workflow.

Activities like Cable Stripping, Punching and Chipping might seem simple in the Indian cable manufacturing landscape but they hold an enormous responsibility. Finally, a badly stripped wire is just one more reason for bad quality or test sample failure and that’s something you want to be looking for if you get rejections at your customer site. That is why it’s so important to get good equipment and to accompany that with accurate measurement tools. SIPCON Technologies fulfills an important function: its products make it possible to measure every stripped, punched or chipped cable confidently enabling manufacturers to create inimitable, compliant and high performing systems. If you are looking to improve your cable testing process, picturize your lab or integrate image-based dimensioning-measurement systems:

Discover accuracy in cable-measuring solutions from SIPCON. Get expert advice on your QC process and Upgrade to the speed and precision of a modern measuring tool Better tools create better cables. Better measurement creates better trust. Contact us on info@sipconinstrument.com or More on our website www.sipconinstrument.com Phone: +91 82229 29966

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi