Cable diameter measurement means checking how thick a cable is from one side to the other. It is measured across the round shape of the cable. This includes both the inner wire and the outer cover or insulation. The diameter is usually measured in millimeters or inches.

Measuring the diameter of a cable is important for many reasons. It helps you choose the right cable for your work. If the cable is too thick or too thin, it may not fit into the connector or machine. This can cause damage or make the cable unsafe to use. Using the wrong cable size can lead to overheating, short circuits, or even fire. It can also affect how much current the cable can carry. That is why it is always a good idea to measure the cable diameter before installing or using it.

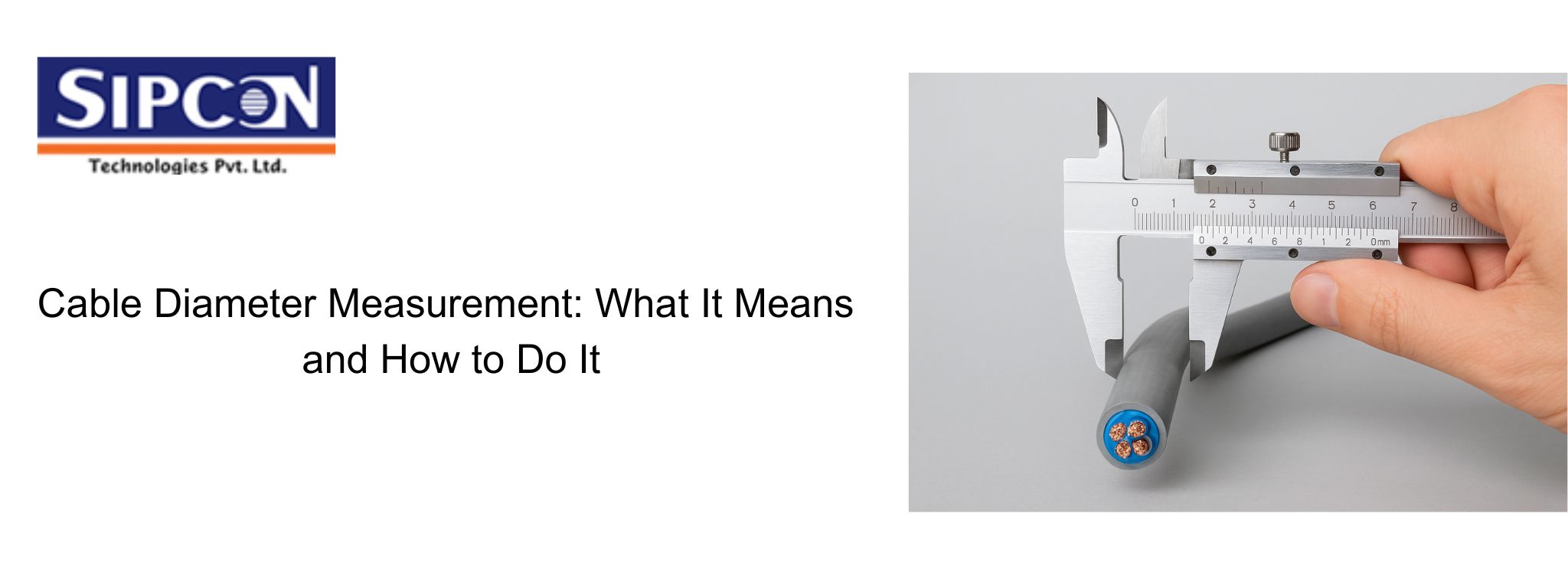

There are a few simple tools that can help you measure cable diameter correctly. Each tool is useful in different situations. A vernier caliper is one of the most common tools. It gives very accurate measurements. You open the jaws, place the cable between them, and read the value on the scale. It works well for both thick and thin cables. A cable gauge tool is another easy option. It has different holes marked with sizes. You insert the cable into each hole until you find the one that fits best. This tool is quick and works well for small and flexible cables.

A micrometer is used for very thin cables or wires. It is more accurate than a caliper. You turn a small screw to close it around the cable and then read the measurement from its scale.

To measure a cable’s diameter, follow these steps. First, choose the right tool for the type of cable. Then, place the cable in the tool gently. Close the tool around the cable without pressing too hard. After that, read the value shown on the scale or screen. Finally, note down the value or use it to check if the cable meets your requirement. If the cable has a thick outer cover, you may need to strip a small part of it to measure just the inner conductor. Only do this if it is safe and allowed for your work.

Many people confuse cable diameter with cross-sectional area. They are not the same. Diameter is the distance across the cable. Cross-sectional area is the space inside the circular shape of the conductor. The diameter is useful when you need to check fitting or space. The cross-sectional area is more important for electrical calculations like how much current a cable can carry. You can calculate one from the other using a formula, but they serve different purposes.

Cable diameter measurement is simple but important. It helps keep your work safe and correct. With the right tool and careful handling, you can measure any cable easily. Always double-check the diameter before starting a job. It can save you from costly mistakes and help your project go smoothly.

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi