Cable stripper machines are the vital equipment for effectively stripping insulation from electrical wires, making them a must-have in recycling, manufacturing, and electrical sectors. Regardless of whether you’re a professional technician or a handyman, selecting the appropriate cable stripper machine can enhance efficiency and produce accurate results.

This guide will take you through everything you need to know—starting from getting acquainted with the types and characteristics of cable stripping machines up to their uses and advantages—so that you can make a well-informed decision and utilize the tool properly.

A cable stripper machine is a machine used to efficiently strip the insulation or outer casing off electrical wires and cables so that the underlying conductor can be easily processed, recycled, or joined. Such machines exist in several forms, ranging from simple manual hand tools to automatic industrial-grade machines, and find application in diverse industries such as electrical work, recycling, and manufacturing.

Also Read– What is 10X Eyepiece and 10X Loupe? Features, Advantages, & Disadvantages

Cable stripping machines are of different types, and each one is meant for particular purposes based on the cable size, type, and volume to be stripped. The main difference exists between manual, semi-automatic, and automatic types.

These are the most basic. In this, the tool is controlled by human beings. They are best used in low-volume wire stripping operations or small-scale workshops. They do have variable blades and need to be fed through and rotated manually against a pressure force that would strip off the insulation. Even though they are inexpensive and easy to maintain, they also call for more work and time.

They provide the middle ground between manual and automatic machines. They typically involve feeding the cable into the machine by the operator, after which the motorized system strips and cuts the insulation. These machines are best suited for medium-sized operations since they enhance productivity without the need to invest in fully automated systems.

The most efficient and sophisticated is the automatic cable stripping machine. These machines are implemented for industrial-scale operations where large quantities of cables must be stripped in a short time with high precision. Automatic machines usually come equipped with programmable controls, digital displays, and adjustable blades that adjust automatically according to the size and type of cable without human intervention.

Also Read: A Complete Guide for Hot Air Oven in Laboratories

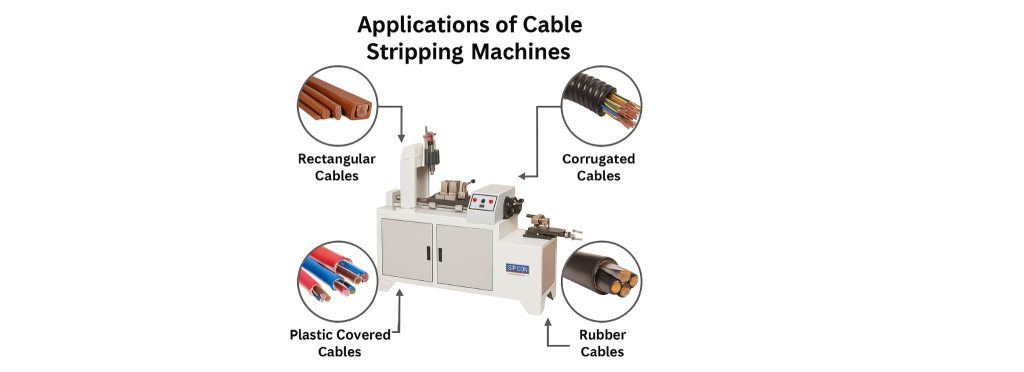

Industrial- and commercial-sized cable stripper machines find their main application in industrial and commercial environments where large amounts of heavy-duty cables have to be processed in a quick time and with high efficiency. These heavy-duty machines are designed to tackle thick, armored, or multi-layered cables that are typical in fields such as construction, telecommunications, power distribution, and recycling.

Overall, large cable stripper machines are irreplaceable wherever armored or thick cables are in question. Not only do they simplify the stripping procedure, but they also provide cost savings, recovery of resources, and efficiency of operation in large-scale industrial settings.

Also Read: What is Fiber Measurement? Everything You Need to Know

Cable stripping machines provide numerous advantages in a variety of industries, particularly when it comes to the processing or recycling of electrical cables. Cable stripping machines are made to strip the insulation or outer covering of cables effectively, and their benefits extend far beyond velocity. The following is an in-depth description of the benefits:

One of the greatest advantages of cable stripping machines is the immense increase in processing time. Stripping wires manually, particularly in large quantities, consumes a lot of time and effort. A cable stripper machine is able to strip many cables in a matter of minutes, which would take hours by hand, making the process faster and increasing throughput in industrial applications. This is particularly convenient in recycling centers and cable manufacturing plants where time efficiency translates into profitability.

Hand-stripping usually results in irregular stripping by-products or harm to the inner conductor, impacting the cable’s usability or diminishing its worth for recycling. Cable stripper machines provide accurate, uniform stripping with adjustable blades and calibrated settings. Such accuracy prevents nicking or cutting of the metal core, maintaining wire integrity for future use or sale.

Though cable stripping machines do involve a high upfront cost, they save significant amounts of money on labor and materials in the long run. They are non-abrasive and minimize wire damage and insulation residue, meaning that more of the precious copper or aluminum can be salvaged. For organizations that process a high amount of cable, this means higher recovery of resources and higher margins for profit.

Contemporary cable stripper machines are designed to strip a broad variety of cables—from flexible, thin wires to heavy-duty, armored industrial cables. Certain machines feature multiple cutting channels or variable blades, so they can strip cables of numerous diameters and materials. This makes them applicable to several different industries, including construction, telecommunications, energy, and recycling.

Manual stripping of cables with knives or handheld devices is hazardous, involving risks of cuts, repetitive strain injuries, or electrical shock (in case cables aren’t safely de-energized). Cable stripping machines minimize these risks considerably by mechanizing the operation and placing the cutting elements inside the machine body, where they cannot directly engage an operator. Operators only need to insert the cable into the machine, reducing personal contact with blades.

Also Read: Cable Diameter Measurement: What It Means and How to Do It

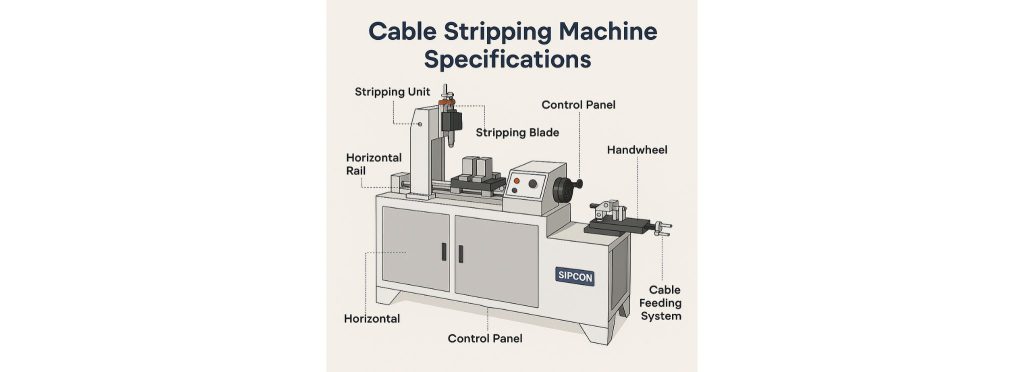

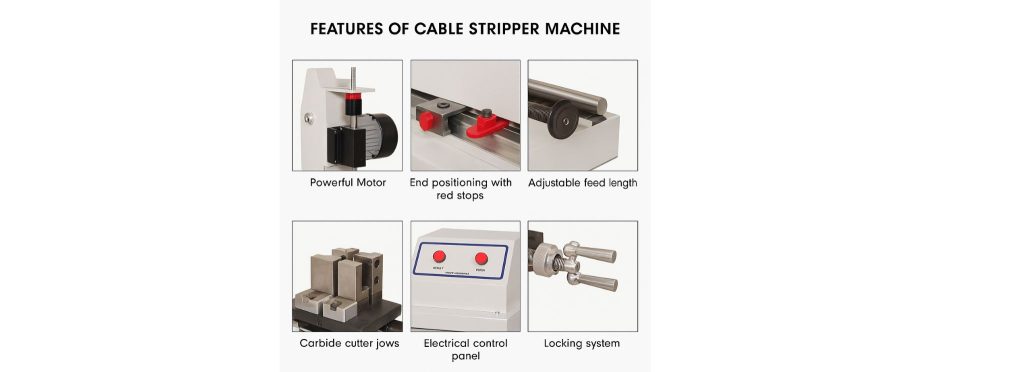

Cable stripping machines come with a range of features designed to enhance their performance, efficiency, and ease of use. Some of its features include adjustable blade depth, Multiple feed channels, Motorized operation, Speed control, Material build & Durability, and Safety features.

Here is a detailed description of these features:

One of the most useful features is adjustable blade depth. This lets the operator determine the depth at which the blades cut into the cable insulation without causing damage to the inner conductor. Adjustable blades are necessary when cutting different kinds of wire because insulation thickness and cable material can be drastically different. Machines with finer blade control ensure cleaner stripping and less waste.

Multiple feed channels are also a common feature, particularly in sophisticated and industrial machines. The channels support a range of cable sizes and shapes, from slender single wires to heavy-duty multi-core cables. Machines with multiple entry points or changeable dies offer flexibility since the operator can change between cable types without requiring a different machine for each type.

The motorized operation is a characteristic of semi-automatic and automatic machines. This minimizes manual labor and maximizes efficiency. The feed rollers and cutting blades are driven by a motor that makes the stripping process quicker and more uniform, especially when stripping long or large wires.

Another key characteristic is the build material and strength of the machine. Quality machines are built from durable metals such as steel or aluminum to allow them to endure long-term use, high torque, and rough industrial environments. Some are even provided with rust prevention coatings to give them a longer life.

Speed control is a feature that is provided in additional models. Adjustable speed levels enable the operator to adjust the speed of the machine based on the type of cable and precision required. For instance, lower speeds can be best for sensitive cables, whereas higher speeds are beneficial in bulk processing of common wires.

Safety measures are important in any stripper machine for cables. These can be safety stop buttons, safety covers, and automatic shut-offs in the event of jamming or overheating. These features provide a safe way of working, particularly when dealing with industrial heavy-duty machines.

Also Read: What is Ribbon Measurement? Everything You Need to Know

It is critical to select the appropriate Automatic Wire Stripping Machine to provide efficiency, accuracy, and safety in wire processing operations. For industrial applications or in the workshop setting, the proper machine can effectively enhance productivity while reducing waste of materials and manpower effort. The major advantages are quicker stripping rates, uniform production, enhanced recycling value, and less operational fatigue. With an understanding of the models, characteristics, and uses of the machines, consumers can make suitable choices that fit their needs—finally maximizing performance and value for money in the long term.

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi