From the concrete jungle of Mumbai to a smart village in rural India, there is an explosion in demand for high-speed internet. This digital revolution depends on a quiet, glass-based information system: optical fibres. But getting the fibre in place is only half the challenge. Being able to rely on every conductor and ribbon in a cable is the difference between healthy and sick networks. Enter the science of accurate optical fibre and ribbon measurement. We at SIPCON Technologies identifies that you can only be happy with pride over everything that´s in our hands to assist.

let us take a closer look at the key tools you cannot do without, when it comes to world-class fibre optic infrastructure

Visualize a freeway with all the lanes of slightly different widths. Chaos would ensue! Likewise, in a fibre optical signal losses or data failures and even whole system fails can result not clearly defined or damaged fibre geometry given as a basis of accurate measurement of optical fibre and ribbon:

Low signal loss: ensuring high quality viewing at distance.

High Availability: No network error and customer’s complaint.

Here are 5 must have tools for all types of fibre optic team in India.

Think of the OTDR the “sonar” for your fibre-optic network. It is perhaps one of the most important tools applicable to field technician.

How it works: It emits a pulse of beam down the fibre, then measures the beam that is scattered or reflected. This makes it possible to generate a “signature” of the entire length of the fibre.

What it tells you: It accurately identifies problems like breaks, splices, bends, and connectors. It quantifies the loss at each of these events and the end-to-end loss of the fibre link.

Why it matters: You cannot solve a problem you have not found. An OTDR shows you where a problem is, so that hours are not spent looking for one.

This may be a tiny little tool, but it is HUGE! Something is important required to perform first, with that good fibre end-face.

What it is: It is a controlled pressure cut; the fibre remains connected, but scored and cleaved without nicks or defects for a flat end-face that is perpendicular to the axis upon completion.

How it works: Though not a numerical readout, its accuracy also dictates how accurate the end-face geometry is (it needs to be good for other measurement tools to take EXFO.

Why it is important: A bad cleave will result in excessive loss in every splice and connection even with the next-generation fusion splicer, and it means that you may not be receiving what you paid for.

This pair is the workhorse for assessing the core parameter, signal loss.

What it is: The beam source shines a steady light with a known wavelength into one side of the fibre. At the far end is a power meter that measures the beam that comes out. The insertion loss is all that changes.

What it is testing: It provides a direct, end-to-end measurement of the total loss (attenuation) of a fibre cable link – all the way from your piece of measuring equipment, through the launch lead and its optical connector interface to the near-end reference connector on an adaptor, along (in series) the fibres in your test sample, into and out of all intermediate connection points which includes splices or fibre-to-fibre links, that maintain signal continuity.

Why you need it: It provides a pass/fail assessment of an installed link, verifying that it will perform according to design.

To splice high-fibre-count cables, ribbons must be used and require special tools.

What we mean: is, a mass fusion splicer aligns and fuses together all 12 fibres in a ribbon at the same time and a ribbon splice organizer provides containment and protection for the spliced ribbons.

What it does: Modern splicers today have built-in cameras and apps that can calculate the alignment of the fibres, offset core, and estimate splice loss before post fusion arc.

Why it matters: It takes hours, and a large amount of skill, to splice high-density cables together It is a key step in the process of rolling out massive FTTH projects across cities in India.

It may be simple, but it is essential, “first responder” on your utility belt.

What it does: It passes a bright red laser light transmitted through the fibre.

What it measures: It does not give you a number but sites problems visibly. You can see the red-light beam through the cable jacket when there is a short or a bad connecting. It verifies continuity and helps to identify the correct fibre when using a bundle of them.

Why it is important: It provides an immediate visual confirmation of fibre quality and allows quick, cost-effective fault detection.

Primary Function: Fault location and characterization

Critical For: Remote network diagnostics

Indian Context: Essential for maintaining pan-India fiber networks

Primary Function: Perfect end-face preparation

Critical For: Low-loss splicing

Indian Context: Crucial for field operations in varying climatic conditions.

Primary Function: End-to-end loss measurement

Critical For: Network commissioning

Indian Context: Vital for meeting TRAI standards

Primary Function: Ribbon fiber splicing

Critical For: High-density applications

Indian Context: Key for smart city projects

Primary Function: Quick fault identification

Critical For: Routine maintenance

Indian Context: best for last-mile connectivity

Digital India, One Metric at a Time

In the sprint to wire an entire country, there can be no trade-off between speed and accuracy. The right instruments for optical fibre and Ribbon testing are not a cost, but investments in the reliability and durability of India’s digital backbone. They allow your teams to form networks which are extraordinary networks that can support the aspirations of a billion people

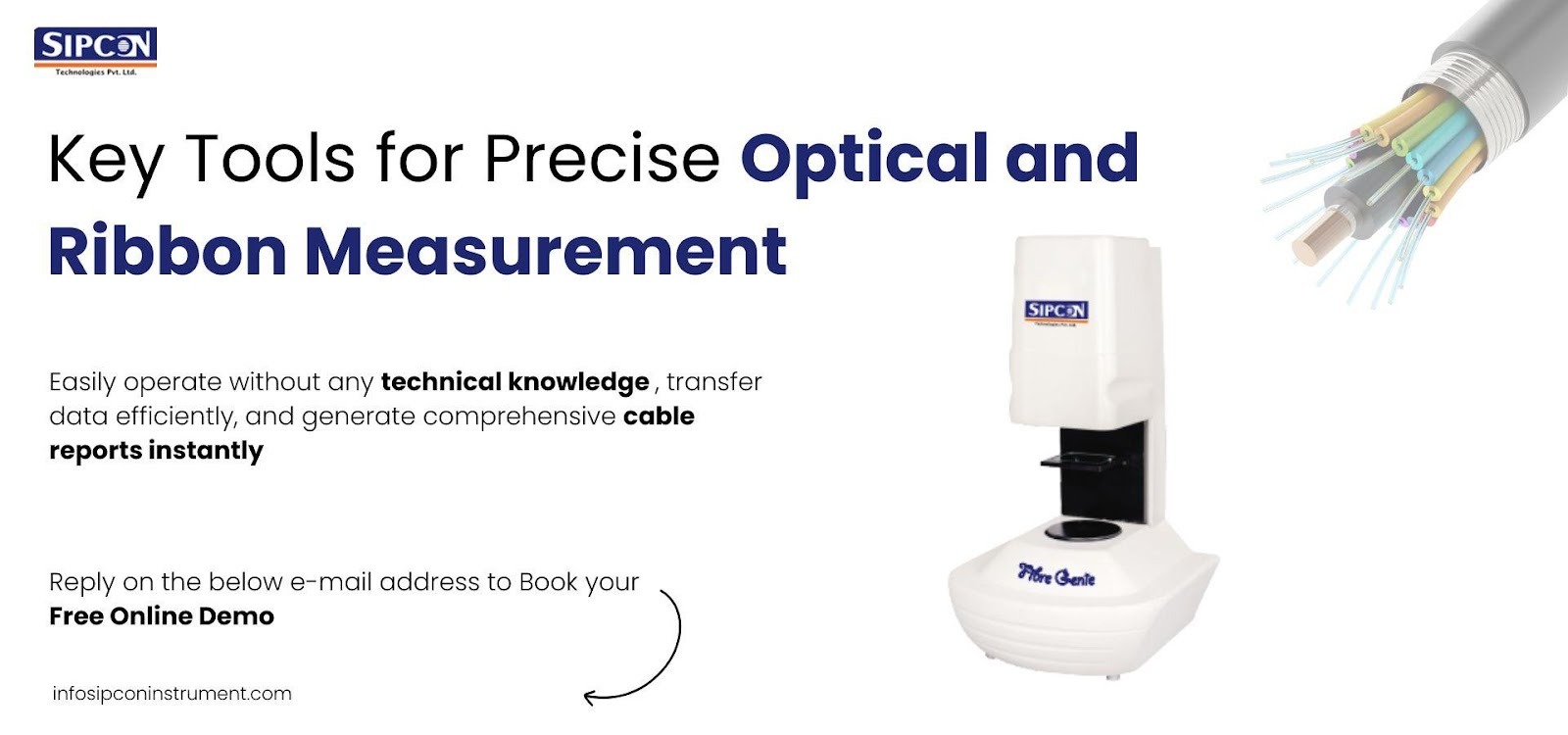

Equip Your Team for Excellence. Do not ever let subpar tools become the weakest link in our data network. SIPCON Technologies delivers précised and reliable equipment for all your optical fibre and ribbon measurement needs with local service and support. Speak to our team of fibre optics experts today to get your perfect kit set up for the job. We would love to connect at info@sipconinstrument.com, or check out our website https://www.sipconinstrument.com

Phone: +91 82229 29966

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi