The Top of the Line in Cable Processing

Efficiency and accuracy are core skiing principles in this fast-paced world of manufacturing. Be it an electric or telecom manufacturing and slicing wires with precision is one of the most important processes in manufacturing.

This is where so-called cable slicers come into play machines designed to shear through with precision and consistency

But in selecting the appropriate system, the whole question is:

We will look at both, compare them and help you to decide for yourself.

Understanding the Basics

But before we do the comparison, let us dissect what each type of slicer even means.

Manual are designed for hand operation Instead; it needs to be aligned and fix by the operator before being used. Conventional blast cabinets are rudimentary in design, inexpensive to get and maintain but make them suitable for workshops and complex part inspections. or specialized large buckets. Think of it hand tools of the cooking universe: reliable, simple, and perfect when it’s more important to be flexible than be speedy.

PLC is short for Programmable Logic Controller, which is basically the “brain” of an automated machine. PLC Cable Slicers are perfectly suited for automatic or semi-automated cutting and provide high accuracy, speed, and repeatable consistency. When programmed, they automatically perform multiple cuts with minimal manual support. These units can be used in high production facilities where quality, consistency and speed are important.

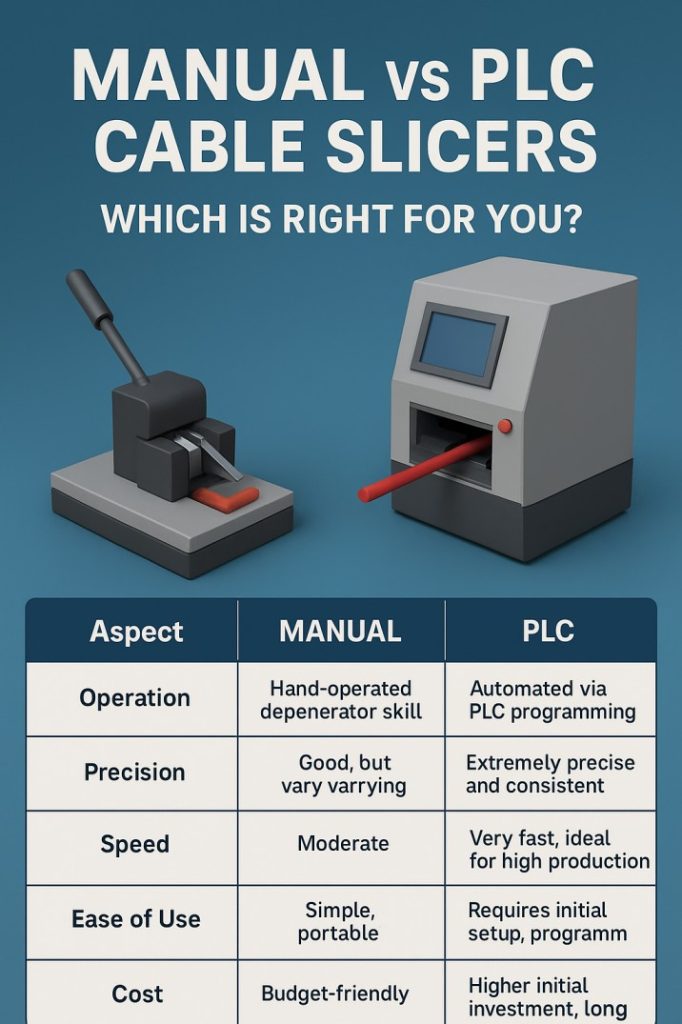

Let us compare the two on key issues:

| Aspect | Manual Cable Slicer | PLC Cable Slicer |

|---|---|---|

| Operation | Hand-operated; depends on operator skill | Automated via PLC programming |

| Precision | Good, but may vary with user | Extremely precise and consistent |

| Speed | Moderate | Very fast – ideal for high production |

| Ease of Use | Simple and portable | Requires initial setup and programming |

| Maintenance | Minimal | Slightly more, but manageable |

| Cost | Budget-friendly | Higher initial investment, long-term savings |

| Best Suited For | Small workshops, short runs | Industrial production, mass manufacturing |

Manual slicing machines are still in use across India” particularly among SME players, electric repair shops and R&D labs. If your operations involve: Low to medium volume production Frequent substitution of cable types or sizes Tight budget considerations your next evolution, then the Manual Cable Slicer is perfect for you. They set up easily, require no programming knowledge and put all the control in the hands of the operator. And for someone starting out in cable manufacturing or testing, it is a practical, hassle-free solution.

PLC Cable Slicers on the other hand are a step toward the future of automation.

They provide unparalleled precision and repeat/reliability, desirable for industries such as automotive wiring harnesses, telecom cables, aerospace, and the electronics industry.

With customizable settings, you can set parameters including length, depth and slicing spacing. Once established, the machine takes charge banishing manual errors and increasing productivity.

They also incorporate data tracking, safety interlocks and quality checks that allow industries in meeting stringent manufacturing requirements.

The decision between Manual vs PLC Cable Slicers is not all about your budget, it is about targeting your machine for your aims.

In the case that your business is expanding and you want to ensure you can grow with it, then a PLC Cable Slicer could make a good investment.

Whereas for smaller jobs or a one-off job, you may still want to rely on a manual slicer.

SIPCON Technologies – Innovative Solutions for Precision

At SIPCON Technologies, we can cater to any manufacturer’s specific requirements. That is why we provide both manually operated and PLC controlled cable slicing solutions, designed for accuracy, longevity, and ease of use.

Our machines are designed and manufactured in India, customised to Indian standards of industry, and supported by experienced help. Because we love helping you save time and money, SIPCON makes it easy to select the sharpening solution that is best for your hands-free operation.

Get the Right Slice for Your Success.

When comparing Manual Slicers with PLC Cable Slicers, the battle is typically fought at the Mile-and-a-Half a Day level! A manual slicer gives you a lower cost option and a back-to-basics experience, while PLC slicers give you automation, precision, and scalability. Regardless of which one, just make sure it fits your long game plan! And, it is worth noting the right tool not only cuts cables; it fuels your productivity. Searching for the perfect solution to cable slicing? Contact one of our experts at SIPCON Technologies today! We will assist you in selecting a model that increases your production efficiency, entertains precision, and offers beyond compare. Get in touch now to check out selection of Manual & PLC Cable Slicers for the contemporary Indian industries. Please feel free to contact us at info@sipconinstrument.com or check out our website at https://www.sipconinstrument.com

Phone: +91 82229 29966

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi