In India, cables are expected to run for years once they are installed. Nobody wants to open trenches or replace lines unless something goes wrong. Over time, cables sit through heat, sunlight, monsoons, dust, and continuous electrical load. These conditions are not occasional. They are part of everyday operation.

When quality is discussed, conductor size or insulation thickness are typically highlighted. These inspections are essential, but they don’t explain why certain cables age well while others exhibit issues much sooner. One area that rarely gets the same attention is how carbon black is dispersed inside the insulation and outer sheath.

The effect of poor dispersion is not immediate. It appears gradually, often after the cable has already been in service for some time.

Carbon black is added to cable compounds mainly for protection. It improves resistance to sunlight, helps the insulation withstand mechanical stress, and supports longer service life in outdoor conditions. In a country like India, this matters because cables are exposed to strong UV radiation and large temperature variations.

However, carbon black does its job only when it is mixed properly. Simply adding the right quantity does not guarantee performance. If the material is not dispersed evenly, the protection becomes uneven as well.

During mixing and extrusion, carbon black particles need to be broken down and spread throughout the polymer. When mixing is insufficient, clusters remain. These clusters behave differently from the surrounding insulation.

This actually means that certain areas of the insulation deteriorate more quickly than others. Weak spots or cracks don’t appear everywhere at once. They start locally and grow slowly. From a testing point of view, the compound may still look acceptable. From a service point of view, the cable is already under stress.

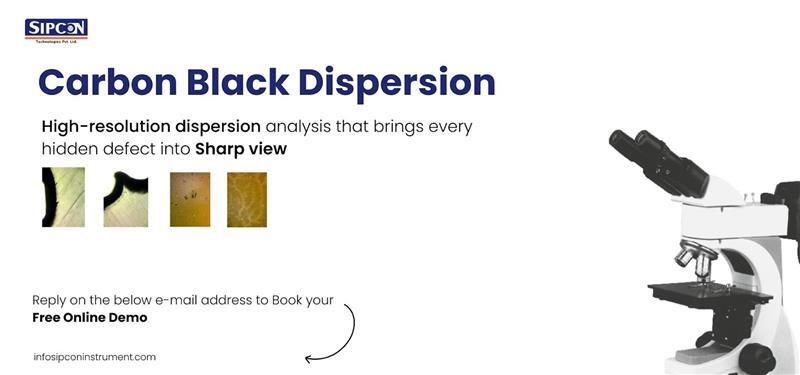

Carbon black dispersion testing is a simple way to see what is happening inside the insulation. Thin slices of the material are checked under a microscope.

Good dispersion looks uniform. Poor dispersion is easy to spot because particle clusters stand out clearly. When these clusters are seen, they usually point back to issues in mixing, processing parameters, or raw material handling. These are things that do not always show up in routine electrical or dimensional tests.

The test does not say when a cable will fail. What it does is highlight risks that would otherwise remain hidden.

Indian Operating Conditions Make This More Critical

Cables in India rarely face one stress at a time. Outdoor exposure, heat, and humidity all work together. Add load variation and aging, and the insulation is constantly being tested.

Where dispersion is poor, these stresses speed up degradation. This may eventually result in cracking, a weakening of the insulation, and an increased risk of electrical problems. Rather than a warning during a routine inspection, the first indication is frequently an unanticipated failure or maintenance problem.

Indian cable manufacturers operate in a tight market. They supply infrastructure projects, utilities, and export clients, all of whom demand constant quality. One of the main issues is batch-to-batch variation.

Dispersion testing helps catch process issues early. It gives quality teams a way to check whether compounding and extrusion are under control. If issues are found at this point, they can be fixed before producing or shipping large quantities.

This eventually lowers customer complaints and boosts product confidence.

Quality and Compliance Perspective

Dispersion testing is not always highlighted the way electrical or dimensional tests are. Still, many specifications depend on material quality that cannot be verified without looking inside the insulation.

Ignoring dispersion raises the possibility of performance problems later in the cable’s life, even though it might not result in rejection right away.

Concluding Remarks

Cable quality is built through materials, process control, and testing working together. Carbon black dispersion testing is a small step, but it plays a role that becomes visible only after years of service.

For Indian cable manufacturers and quality professionals, paying attention to dispersion is a practical way to improve long-term reliability under real operating conditions.

For teams reviewing carbon black dispersion testing practices in Indian cable manufacturing, SIPCON can share application-based observations and testing considerations.

us@sipconinstrument.com

www.sipconinstrument.coms

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi