The surface quality is very crucial in the manufacture of cables in terms of performance, safety, and reliability of the product. Bonding and conductivity of insulation, as well as the final long-term durability issues, can be compromised by the smallest flaws in the cable surface of a high-voltage power line or a fiber-optic cable, as well as in a vehicle wiring.

To encounter these issues in the cable manufacturing industry, a cable buffing machine is generally used. This advanced machine ensures that cables meet both functional and aesthetic requirements before moving to the next stage of production. In this article, learn everything about cable buffing machines including their working and applications in various industries.

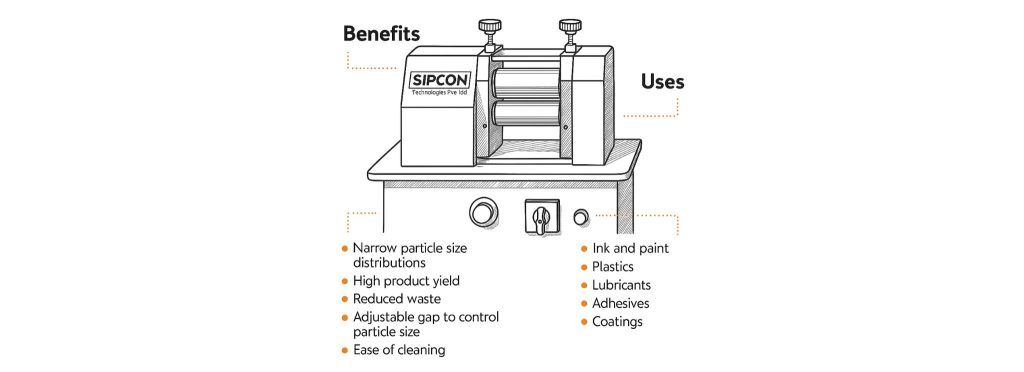

Cable Buffing Machine is a high-performance tool designed to clean and polish the outer surface of cables by removing oxidation, dirt, and surface impurities. It ensures a smooth and clean cable surface for better insulation, improved conductivity, and enhanced coating adhesion in further processing stages.

It makes the buffing of the entire cable length uniform, which saves manual effort, turns the operation more consistent, and decreases the complications linked with poor surface preparation. Such an inclusive approach not only increases efficiency but also improves the quality and durability of the cables manufactured.

Sipcon’s cable buffing machine is ideal for PVC, XLPE, and rubber-insulated cables. This machine enhances production efficiency, minimizes material rejection, and ensures optimal performance of downstream processes, such as printing or marking.

Also Read : Complete Guide to Choosing and Using Cable Stripper Machines

A Cable Buffing Machine works by passing the cable through rotating buffing wheels or abrasive pads that clean and polish its surface. The cable is rolled through the machine, where impurities such as dust, oxidation, and minor defects are eliminated. It provides a clean finish in an effortless process to enhance better attachment of the insulation and cable performance.

Cable Buffing Machines are employed during the fabrication of wires and cables to clean outer surfaces aggresively, preparing them to be insulated, coated, or otherwise processed. They assist in upgrading the surface quality with better adhesion, conductivity, and performance.

| Parameter | Details |

| Cable Diameter Range | 5 mm – 40 mm |

| Cable Material | PVC, XLPE, Rubber |

| Brush Speed | 100 – 200 RPM (adjustable) |

| Power Supply | 220V AC, 50/60 Hz |

| Motor Power | 120 W – 200 W |

| Machine Dimensions | 285 × 220 × 320 mm (Approx.) |

| Weight | 25 – 30 kg |

| Control Type | Manual / Digital (Model Dependent) |

| Safety Features | Protective brush cover, cable guide |

| Optional Add-ons | Auto-stop, quick-change fixture |

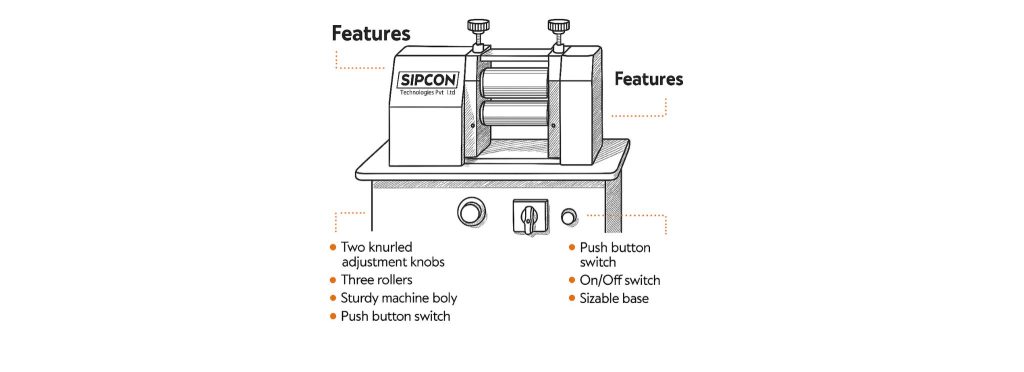

The features of a cable buffing machine vary based on the industry requirements and machine model. A typical buffing machine consists of the following features:

Also Read : What is 10X Eyepiece and 10X Loupe? Features, Advantages, & Disadvantages

Designed to clean cables before printing or further processing, Sipcon Instrument offers a high-quality cable buffing machine to achieve flawless cable surfaces. It efficiently eliminates dust, residues, and micro-imperfections that can affect insulation performance or print clarity.

The cable buffing machine is inserted in the line prior to printing or marking, at locations where clean and smooth cable surfaces are required. The machine is adaptable in terms of measuring the diameter and the material of the cable, thus making it suitable for different kinds of cables.

This enhances the printing quality and improves and intensifies the bonding between the insulation layers. With the application of different types of cables, including PVC and XLPE, the Sipcon’s cable buffing machine maintains uniformity in the production lines and helps in an effortless manufacturing process.

Also Read : A Complete Guide for Hot Air Oven in Laboratories

Frequently Asked Questions

Q. What is buffing in fiber optics?

A. Buffing in fiber optics is the process of cleaning and refining the cable surface but in aggressive manner. It removes oxidation, dust, and impurities to ensure a smooth finish. This step is crucial for enhancing insulation performance and preparing the cable for better coating adhesion.

Q. What is the use of a Cable Buffing Machine?

A. A cable buffing machine is used to clean the outer surface of fiber optic cables. It removes dirt, oxidation, and other residues, helping improve insulation and ensure uniform coating. This enhances the overall quality and reliability of the cable during further processing.

Q. Can all types of cables be buffed using this machine?

A. Most cable buffing machines are designed for specific cable sizes and types. While many support standard fiber optic cables, compatibility depends on the machine’s design and settings. Always check the machine specifications to ensure it suits your cable type and application.

Q. What is the price of a Cable Buffing Machine in India?

A. The price of a cable buffing machine depends on factors like size, features, level of automation, and brand. Machines with advanced controls or larger capacity generally cost more. For accurate pricing, it is best to contact verified manufacturers or authorized suppliers.

Q. Where to buy a genuine Cable Buffing Machine?

A. You can buy a genuine cable buffing machine from trusted industrial suppliers like Sipcon Instrument that offer high-quality and global standard machines. Always look for sellers who offer technical support, warranty, and installation assistance to ensure product authenticity and long-term reliability.

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi