From the scorching summer days of 50°C in Rajasthan to the humid and salty coastal air of Mumbai, and the frigid winters of the Himalayas, the climatic conditions in our country are more diverse and harder to please than possibly anywhere else in the world. This level of climatic variety has dramatic implications on the straining of the very infrastructures that drive our progress: our cabling.

Have you ever touched a cable on a hot tin roof and felt that it was unusually warm? Or have you reached for wires in the winter cold and felt the wires were hard and brittle? These are not just trivial matters; these are signs that, if left unchecked, will result in failure. We, at SIPCON Technologies, know that the safety of your home, efficiency of your industry and reliability of our national infrastructure all hinge on a process that no one really thinks about: cable thermal testing.

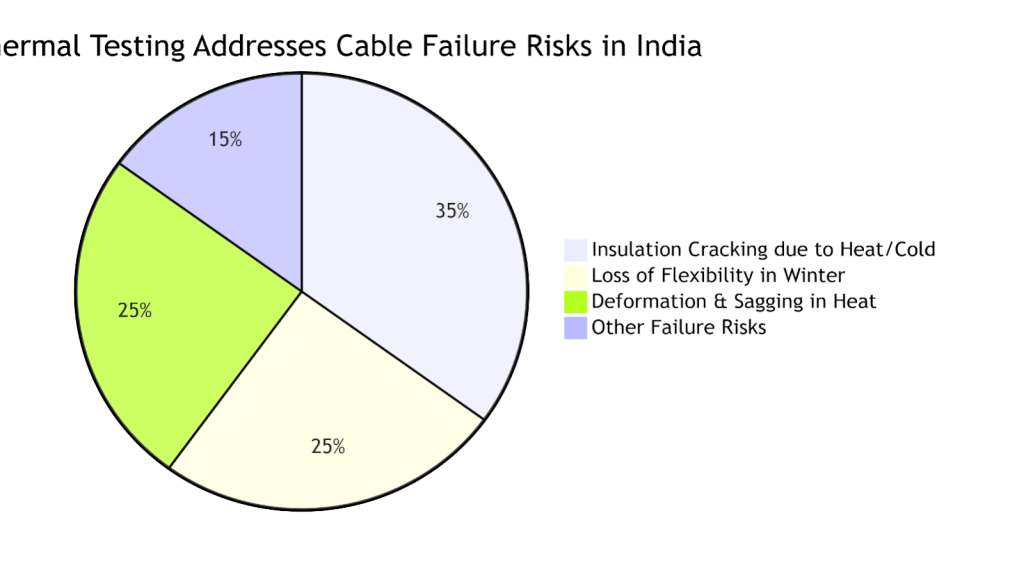

In our environmental conditions cables are continuous respiration, growing, and growing in the mid-afternoon heat and then contracting, tightening, and coolness of night hits. This daily thermal cycling cannot be a crucial endurance test to Passive Components. The consequences of not performing timely cable thermal testing can result in:

This is why for us at SIPCON, cable thermal testing is a mission, not a process. It is ensuring that the wires hiding behind your walls can, without incident, stand up to a lifetime of Indian weather.

We replicate years of environmental stress in a few days in our laboratories, which are equipped with leading-edge technology. Here is one detailed look at how we test cables:

Think of a cable strung across a warehouse in Chennai. With the heat, will it sag and risk damaging itself? This is where we find out! We put a cable sample underweight in a temperature-controlled environment, or oven, while at an elevated temperature (Temperature variance can be 80°C, 100°C or to specific regulations). We assess accurately its deformation. Quality cables have little deformation and we can only conclude its strength under thermal loading is acceptable.

How will this cable perform after 20 years? Lucky for you, we have an accelerated ageing test. In this test we train the cables to high controlled temperatures for long durations and effectively speeds up a parallel time of service months in a period at a high temperature. After this, we collect and analyze the material for changes in tensile strength and elasticity. This test will finally identify that the cable will be a reliable or become a brittle, dangerous piece of equipment at the age.

This test is important for an installation in North India or cold storage applications. We take samples and cool them to low temperature below -25°C or lower) and bend the sample around a predetermined rod. An unsuitable cable would crack or fracture during this process, while a SIPCON-two educationally certified cable bends easily, proving its pliability and safety in even the most extreme conditions.

Imagine you live in Jaipur and it was really hot all day. Then suddenly, you get a storm with heavy rain. You cannot believe it, but the temperature changes are quite shocking for materials. In the thermal shock test, we quickly change cables from a very high temperature to a very low temperature, many times. After this, we look for cracks, breaks or loss of integrity. This ensures that our cables can reasonably handle our unusual weather patterns.

It is Not Only a Cable, It Is a Lifeline

A cable is not just a wire, it is literally the lifeline of your house, your business, and all our interconnected systems. When it comes to choosing a cable that has successfully undergone the high-performance cable thermal testing at SIPCON, you are not just deciding to buy a cable, but instead you are choosing safety that is unmatched, lower long-term maintenance costs, and peace of mind knowing you will not have to worry about dependability. The next time a heat wave hits or wintry cold hits, you can rest assured knowing that the wiring of your power system is reliable and will last.

Safety is Important – Let Us Talk!Do not let the safety and performance of your applications to take risk. Whether you are a builder, a project manager, or a procurement officer to know the materials you are using will function in Indian applications. Call our thermal testing experts at +91 82229 29966 today for a consultation. Let us help you build a safer and more reliable India. Contact us at info@sipconinstrument.com and check out our website at https://www.sipconinstrument.com.

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi