Toggle press has become a common name in manufacturing units dealing with cable, rubbers and plastics. There’s a scientific explanation behind its corporation but before diving deep into toggle press, one should be versed with the terms like tension and tensile testing.

A toggle press is a precision mechanical device that uses a toggle linkage mechanism to deliver high force at the end of its motion. Commonly used in industries like automotive, electronics, and metal fabrication, it performs tasks such as cable punching, riveting, embossing, and press-fitting.

Simply put, a toggle press is a tool used in industries to perform jobs that require a lot of force but have limited space. Instead of using electricity, a toggle press uses air pressure to push forcefully through a set of levers. Most toggle presses are fixed to a workbench. To use a toggle press safely, it should first be mounted to a bench. Mounting the press usually involves using bolts to hold it in place.

A toggle press operates using a toggle linkage system—typically a pair of arms connected by a pivot—that converts a small amount of input force into a much larger output force. As the arms approach a straight-line position, known as a dead center, the force output peaks, allowing the press to deliver high pressure with minimal input.

The mechanism has a main lever connected to a smaller lever, which pushes a piston down onto the material, pressing it onto the table. Using toggles increases the pressure on the material by making the force stronger. Because of this, toggle presses can apply more force than other methods using a hammer. Below is the step-by-step process of toggle press working mechanism –

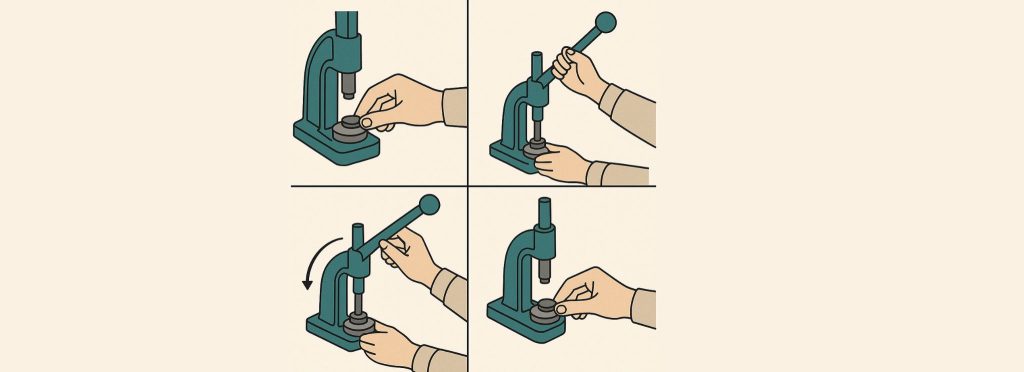

Step 1: Position the Workpiece: Put the material on the press table, making sure it is set in place.

Step 2: Activate the Mechanism: For manual presses, pull the lever; for powered presses, activate the air or hydraulic system.

Step 3: Toggle Lever Movement: The main lever moves, which is linked to a smaller lever. This system increases the force applied.

Step 4: Force Transfer: The toggle system sends the increased force down to the piston or pressing plate.

Step 5: Pressing Action: The piston or plate moves down and presses hard on the workpiece.

Step 6: Release: Once the pressing action is complete, the toggle mechanism releases and the material is removed from the press.

Toggle presses are multi-purpose tools that work in different situations where the requirement of strong pressure and accuracy. Tasks like cutting, punching, stamping, riveting, and assembling here pressure and accuracy are required. They make the user’s force stronger, making it possible to apply a high force in tight spaces.

Toggle press offers several benefits in manufacturing and processes. They offer a fast and easy method to press materials during tasks like stamping, riveting, and shaping. Here are some major benefits of the Toggle press:

Toggle presses offer rapid, smooth operation with minimal effort, making them ideal for high-volume tasks. Their mechanical advantage ensures consistent performance with less manual input. This speed and efficiency boost productivity, reduce cycle times, and make them a valuable asset in fast-paced manufacturing or assembly environments.

Versatility is a key benefit of toggle presses, as they can handle a wide range of tasks, such as punching, bending, forming, and riveting. Their adaptability makes them suitable for various industries, allowing users to perform multiple operations with a single tool, saving both space and investment in extra equipment.

Toggle presses offer a significant power advantage by multiplying the input force through a lever mechanism. This allows users to apply high pressure with minimal effort, making them ideal for tasks that require strong, consistent force. Their mechanical design ensures efficient energy use and powerful performance in a compact form.

Toggle presses offer a reliable method for shaping and cutting metals with accuracy. Their high-force output and mechanical advantage make them ideal for creating holes and forms in metal materials. This cutting mechanism ensures clean, accurate results, enhancing productivity and consistency in metal fabrication processes.

The linkage mechanism in a toggle press multiplies the applied force through interconnected levers, allowing high pressure with minimum effort. This efficient force transmission ensures precise and consistent operation. It is ideal for tasks that require accuracy and strength. It also reduces operator fatigue and improves productivity in repetitive applications.

In simple terms, tension is the force applied to a piece of cable in the form of stretching, pulling, or compressing. Tensile tests, hence, allow you to assess the ability of a piece of wire to endure tension in varying conditions. You do not want the cable to break or crack, or you do not want the insulation to come off when the cable is subjected to tension.

Tensile testing is the test that tests with the cables’ stretchability and material elongation properties. Tensile strength is the maximum force (or stress) that can be exerted on the material before it breaks or fails before the deformation takes place permanently on the cable. The point at which the deformation occurs is called the yield point of the material. During any tensile test there are other factors too that can be measured such as Young’s Modulus, Tensile Strains and Elongation.

To use a toggle press, first securely mount it to a workbench. Place the material or workpiece on the press table, ensuring it is stable. Engage the hand lever for manual models or activate the pneumatic/ hydraulic system for powered presses. The toggle mechanism multiplies the force, pressing the piston or plate downward onto the material. This creates a precise, high-pressure effect ideal for bending, punching, or shaping. Once the press completes the tasks, release the lever and remove the workpiece.

Place the plastic blocks on the work platform

Place the test piece flat on the plastic backing plate

Place a suitable cutter on the test piece

Turn the disk clockwise for punching.

Take out the test piece

Frequently Asked Questions (FAQ)

Q. What is a toggle press?

A. A toggle press is a hand-operated machine used to press, bend, punch, or join materials. It works by pulling a handle that applies strong force with little effort.

Q. How does it work?

A. When you pull the handle, a special joint (called a toggle mechanism) moves and locks to create strong pressure at the end of the stroke. This helps in doing tasks that require force without using electricity.

Q. Is it safe to use?

A. Yes, toggle presses are safe if you follow the instructions. Keep your hands clear while pressing and wear safety glasses for extra care.

Q. Can I get different sizes or types?

A. Yes. Toggle presses come in many sizes and pressing capacities. You can even get custom tools and dies made for your specific work.

Q. How strong is a toggle press?

A. They come in many strength levels, from around 100 kg to over 2 tons. Choose the one that fits your job.

Q. Does it need regular maintenance?

A. Not much. Just keep it clean, oil the moving parts sometimes, and check if anything is getting loose or worn out.

Q. Where can I buy a toggle press in India?

A. You can buy one from local tool suppliers or directly from trusted manufacturers online. Always check the quality and after-sales support.

Helping clients solve complex dimensional measurement challenges with a range of robust measuring systems.

+91-82229 29966, 0171-2699668

info@sipconinstrument.com

LocationPlot No 280, HSIDC Industrial Estate Saha Ambala, Haryana 133104, India

© 2024 Sipcon. All Rights Reserved. | Privacy Policy | Crafted with by Chhavi